Air Pollution Control System

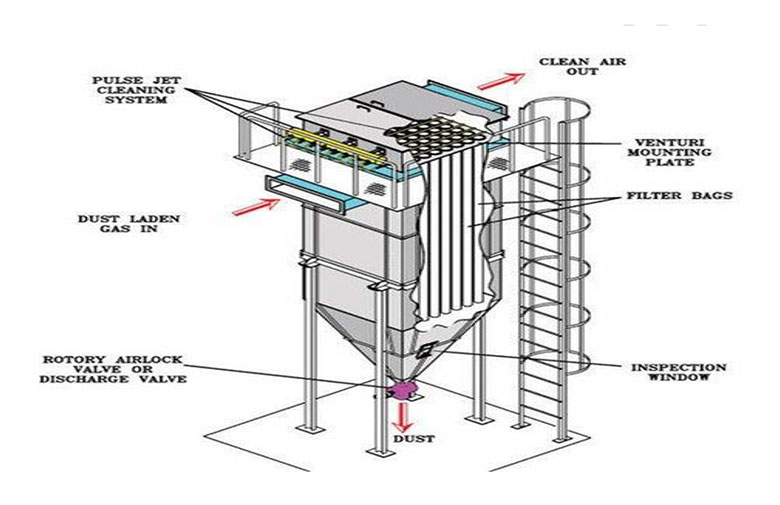

Bag House

Among dust collection systems, baghouses are the most widely used. The reasons why are two fold: baghouses are both highly efficient and cost-effective. Baghouse systems are engineered to collect, capture, and separate dust and particulates from the air. That said, how do baghouses work?

Baghouses utilize fabric filter bags or pleated filters arranged in rows and mounted vertically in a sheet metal housing. They are designed to receive dusty gas from fugitive or process sources, capture the particulates, and exhaust clean air. Typically, via an induced draft blower, the dusty gas stream is drawn into the baghouse through a duct system. The gas stream then passes through the filters while particles remain on the filter media surface, thus separating the particulates from the air. Over time, as the dust begins to build up and form a filter cake on the filter surface, various cleaning systems are used to remove the dust from the filters.

How the dust is collected and how the baghouse is cleaned depends on the type. The most common baghouse cleaning systems is pulse-jet,

Pulse Jet System

The pulse-jet is ubiquitous in industrial dust collection. These industry workhorses boast no moving parts in their basic configurations and allow collection efficiencies greater than 99.9%. In the pulse jet dust collector, the dusty airstream usually enters from below the bags or filters. It is pulled upwards through the filters, where dust is captured on the exterior surface, and clean gas passes through to the clean air plenum side for exhaust. When fabric filters are used, the bags are supported by internal wire cages. The pulse-jet cleaning cycle is controlled by a solid-state timer which sequentially pilots’ “pulses” of compressed air in the reverse direction of filtering into blow pipes mounted above each row of filters.

When activated, the reverse pulse air pulses travel down the length of each bag in the given row, causing a ripple effect, dislodging and releasing the caked dust into the hopper at the base. A main advantage of the pulse jet baghouse is that it does not have to be taken off-line to clean the filters. With the dust removal programmed for regular or on-demand intervals, the system offers more complete cleaning and reconditioning of the filter bags than the other systems. Operating costs are minimal outside of the cost of compressed air for cleaning.

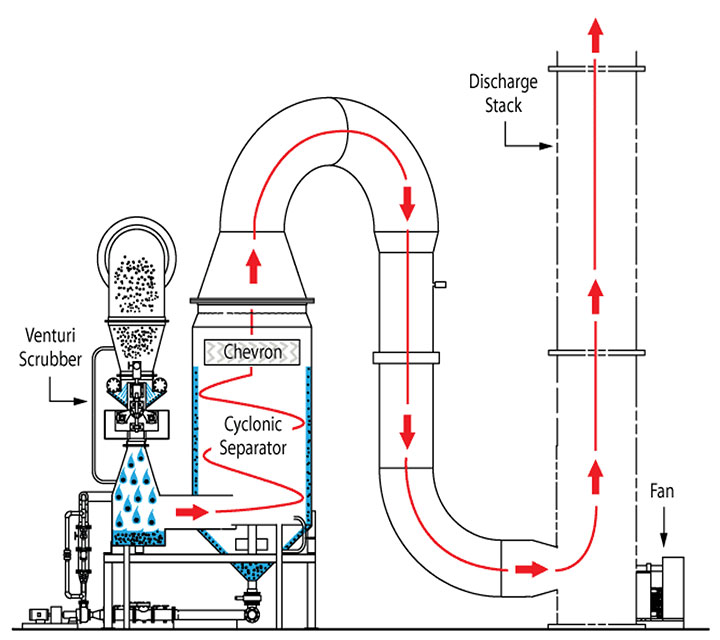

Wet Scrubber

Scrubber

The term wet scrubber describes a variety of devices that remove pollutants from a furnace flue gas or from other gas streams. In a wet scrubber, the polluted gas stream is brought into contact with the scrubbing liquid, by spraying it with the liquid, by forcing it through a pool of liquid, or by some other contact method, so as to remove the pollutants.

Induced Draught Fan

An induced draught fan (ID fan) is provided to maintain a negative pressure in the furnace by sucking the products of combustion from it with a slight positive pressure at the discharge end the bottom of the chimney/stack.

This positive pressure, assisted by the stack effect of the heated chimney (∼120°C), causes the flue gas to leave the chimney and mixes it with the surrounding atmosphere. Dampers, automatically controlled, are also a part of the SG plant that maintains the approximate furnace draught within a safe margin.