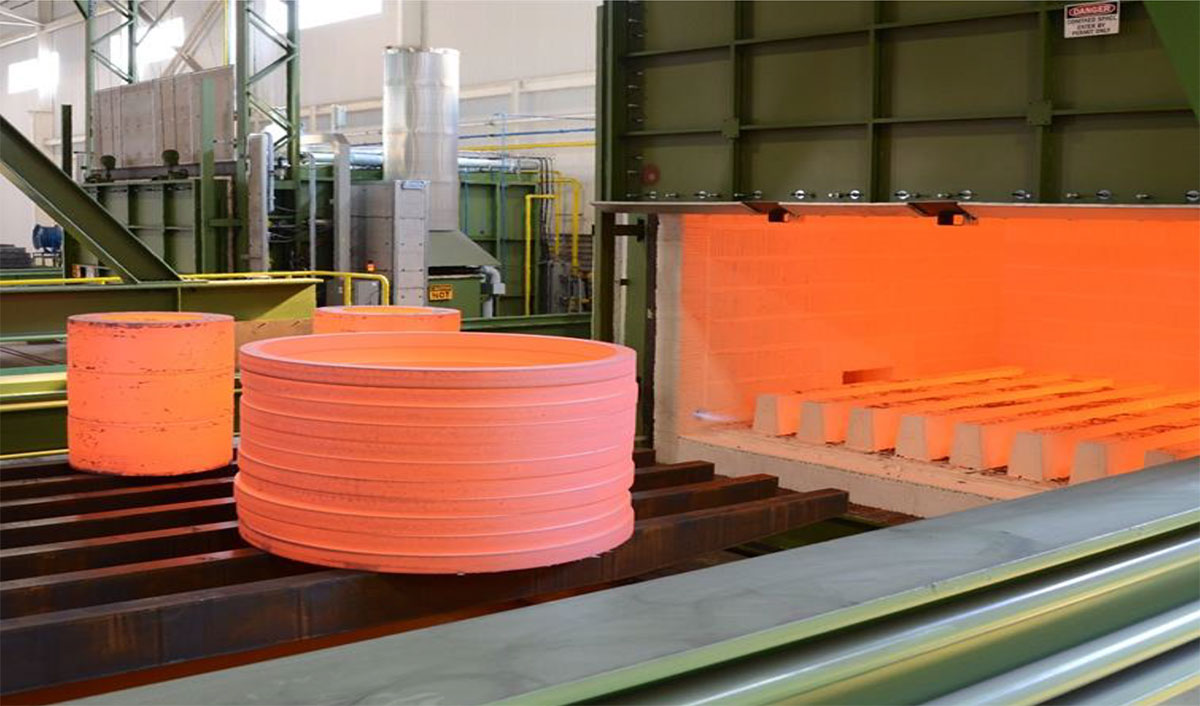

Heat-Treatment Furnaces

The heat treatment furnaces are used for annealing, Hardening, tempering of stainless steel, high carbon or spring steel in coil form. The sheet is pulled through the furnace by means of a coiler coupled with driving mechanism and the coil is loaded on an uncoiled.

MFI have in stores, the finest quality of Heat Treatment Furnace. These machines are made from superior quality raw material, procured from the finest vendors in business. Advanced machinery and experienced work force is used in making the product long lasting and efficient. Further, our products are thoroughly tested to meet international quality standards and satisfaction of our valued clients. To cater the requirements of our clients, we design these products in varied specifications.

Quenching Cranes

The design is based on the customers’ requirements, in many cases these Quench Systems are integrated with load and unload Robots or custom manipulators to ensure specifications are met.

MFI simulation tools (computational fluid dynamics CFD) is used in order to select the best quenchant agitation systems and flow distribution technology.

- Quench tanks for steel castings and forgings

- Air quenching for steel castings and forgings

- Batch With Agitation

- Quench tanks for aluminum casting

- Spray

- Air quenching chambers for aluminum castings.

Foundry Sand Mixer

MFI makes "Auto Mix" Foundry Industries Sand Mixer is widely used in foundry, paint and pigment industries for manufacturing of distemper paints, ER - series of edge runner is also widely used in pharmaceutical industries for preparing pastes, in synthetic industries for preparing pigments and also used for manufacturing various kinds of putties. MFI Runner is based on latest technology, its balanced roller and adjustable scrapper, increase the efficiency of the machine resulting in more production at low cost. MFI - Series of Edge Runner is a result of an inbuilt R & D research, highly experienced and technical staff.