Lead Smelting Rotary Furnace

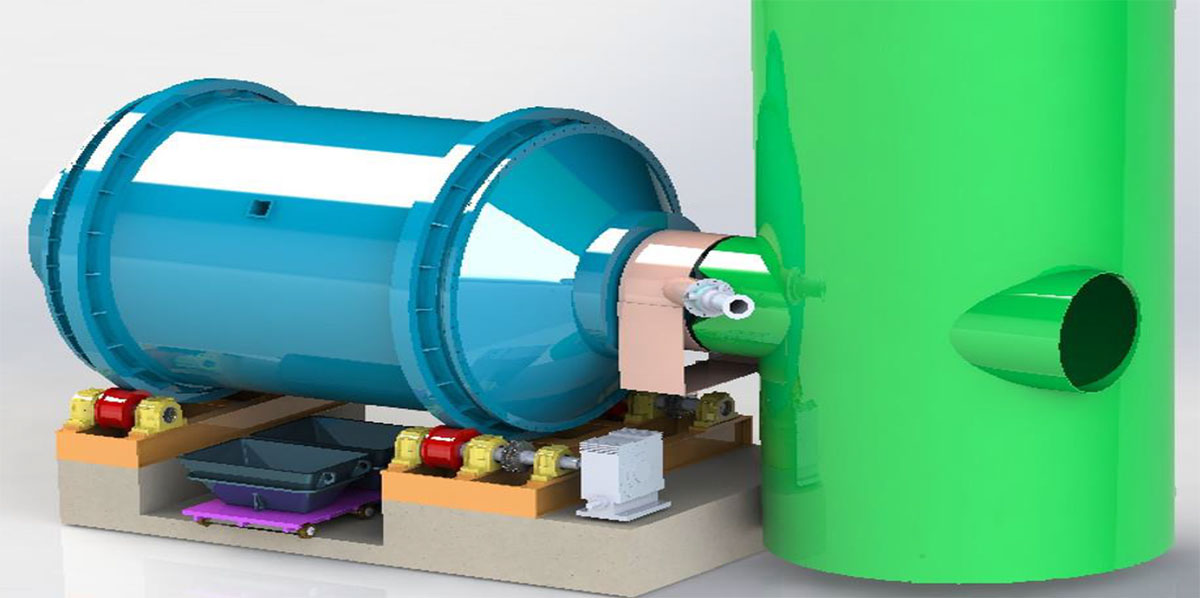

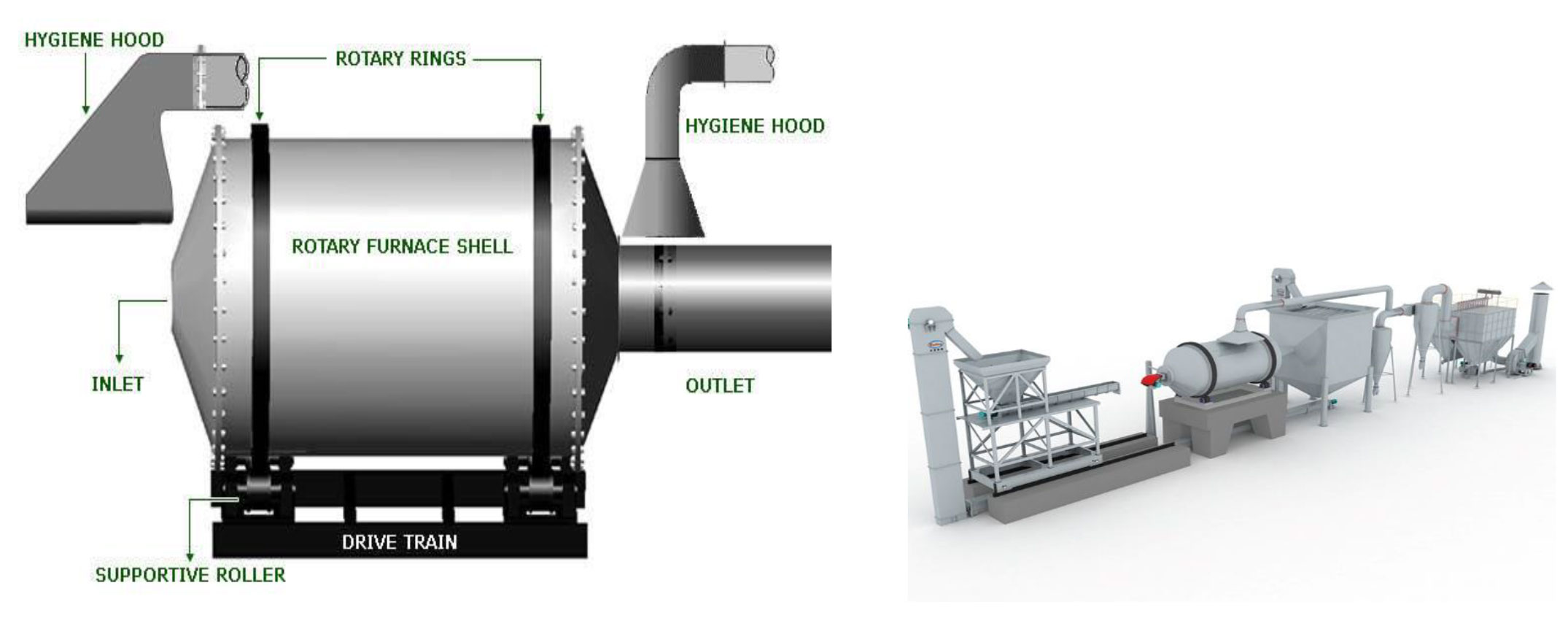

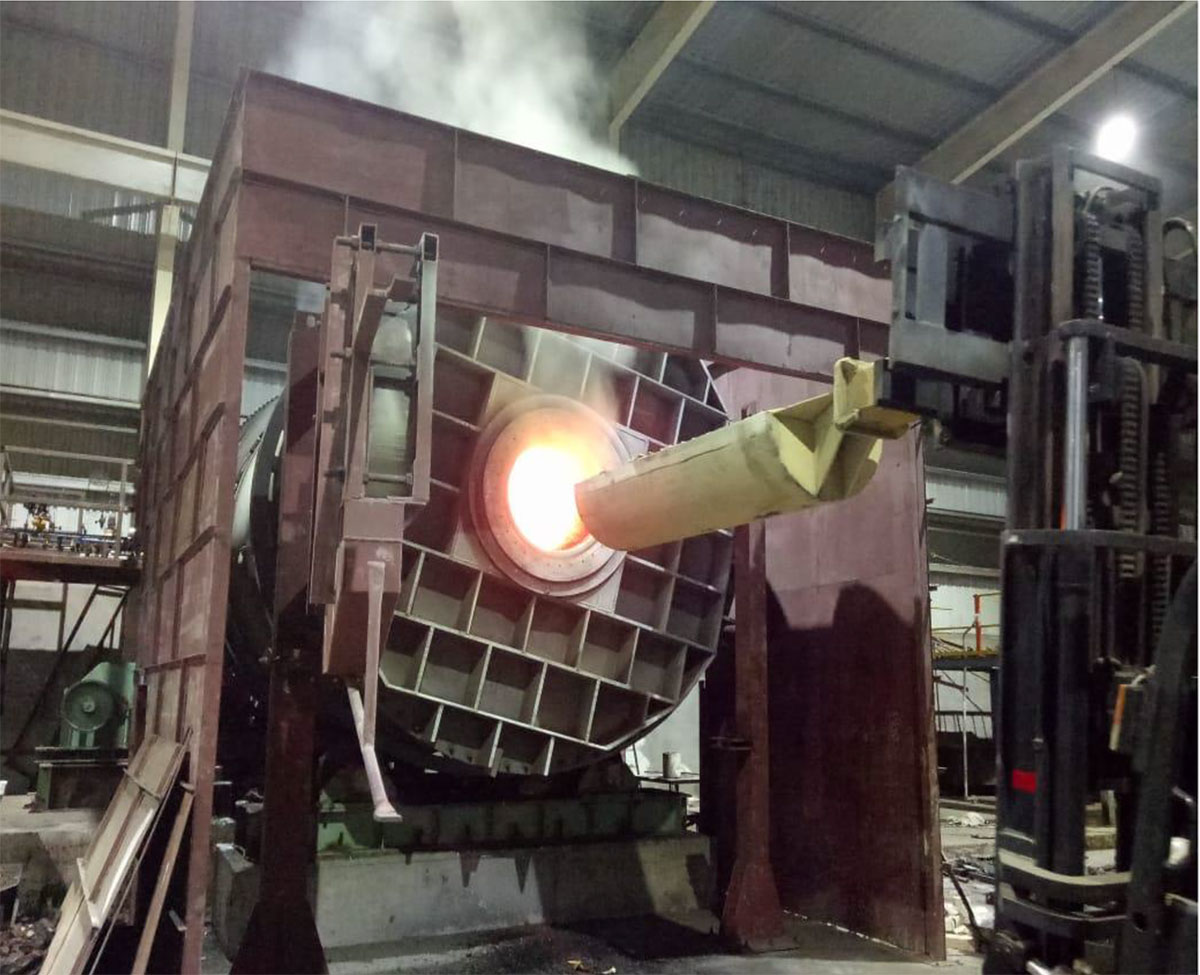

M-Tech Furnaces (India) Rotary Furnace for Recovery of Lead from Used Acid Batteries We design and fabricate High-Temperature Oil Fired and Gas Fired Rotary Furnace for processing and smelting of lead from sources such as Used Batteries, Lead Waste material, Oxides recovered from BBSU, Dross, Sinter Ore, and other multiple sources. Our fabricated rotary furnace has the versatility to reach an optimum temperature up to 1250 Deg. C. Rotary Furnace is connected with exhaust refractory lined damper which carries the hot flue gases to settling temperature. The Settling chamber settles the gases and with the decrease in temperature, it moves on to the cooling line making its way to the baghouse which filters the oxide and gases so the same can be sent to the chimney for outlet emissions.

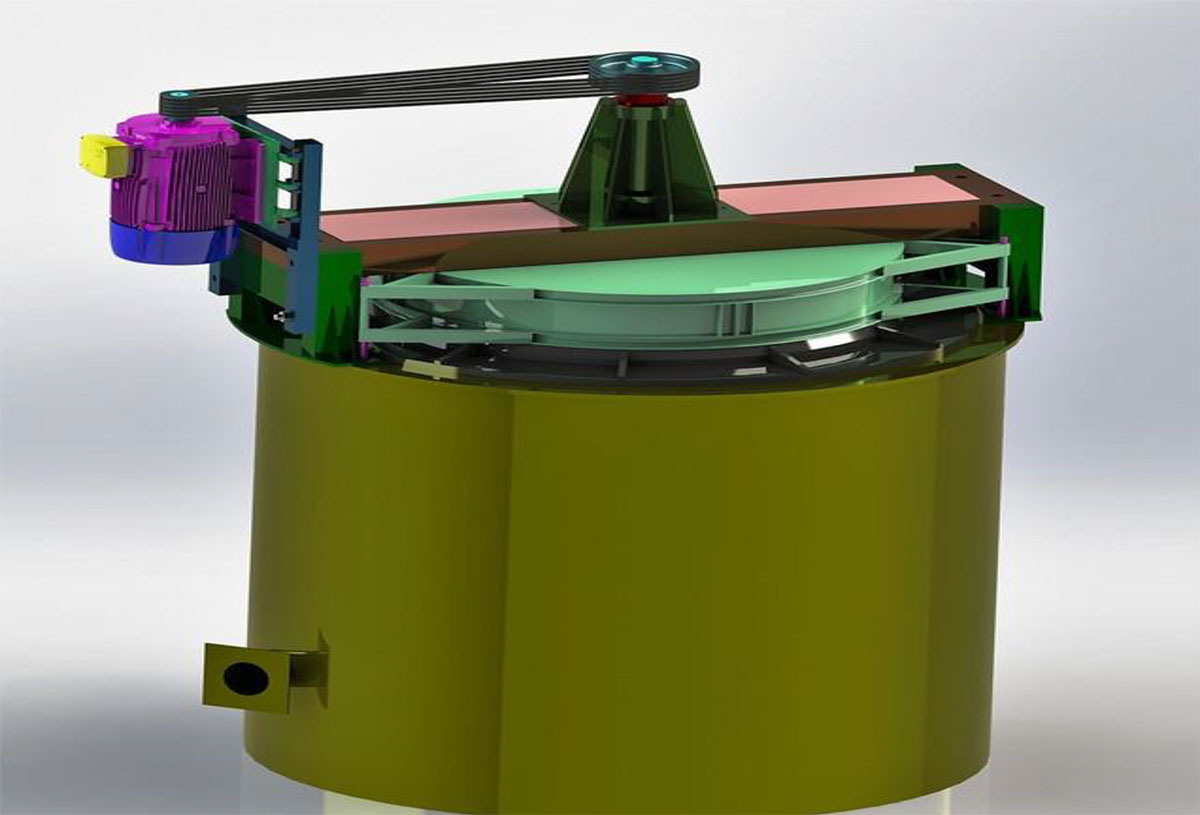

Lead Refining Pots

In order to make quality of lead suitable for its different uses, different variations of pot melting processes are employed. These include – “Re Melting” for removal of slag, Refining Pot for attaining required purity levels and “Alloying” for producing various alloys of lead. The equipments used are the same, the consumables and the processes. The Refining Pot for Lead recycling (or Melting Pot or Alloying Pot, as it is variously called) is a mechanical mixing device with a pot and a heating arrangement. The inner pot is made of heavy MS plate with dish end bottom. It is placed within a jacket of refractory bricks, which in turn, are protected by an outer cover of MS plate with reinforcements. The pot is covered at the top with opening for feeding lead ingots and is provided with an electro - mechanical mixer. At the bottom, a heating source, usually an oil-fired burner, is provided to heat the pot and to melt the lead.