Aluminum/Copper Melting cum Holding Skelenor Furnaces

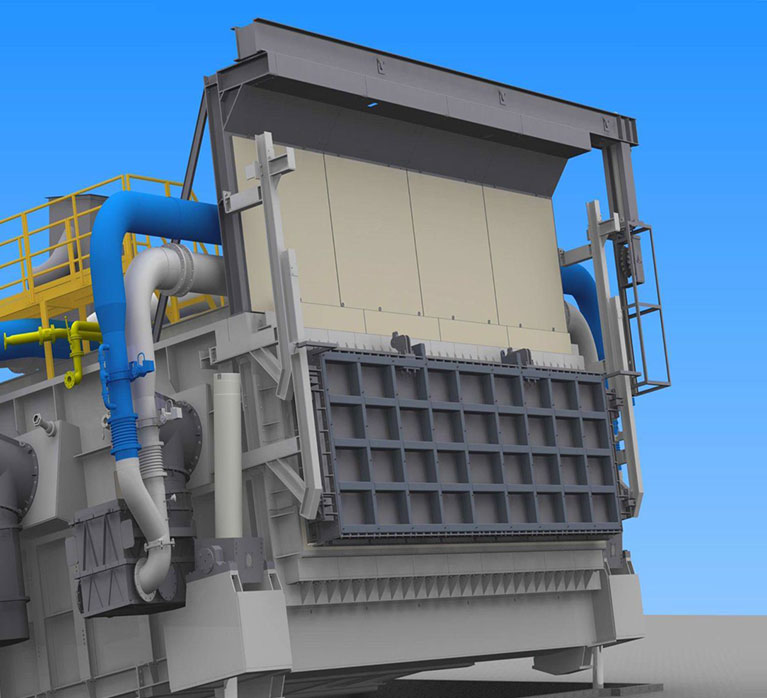

These types of Furnaces have a melting chamber fitted with Burners & Recuperator. After Melting the Aluminum, the furnace tilts on a desired angle in order to dischargethe molten metal. Tilting arrangement can be either Hydraulic or Mechanical type.

We fabricated our complete range by using superior quality raw material and other electrical components, which help us to meet the international quality standard. Their demand rises in the universal market because it has the capability to withstand high temperature or face different challenging situations.

MFI Hydraulic Tilting Aluminum Melting Skelner Furnace manufacturers, suppliers, and exporters of India, we ensure that you will never feel regret over your decision to choose us for your industrial products & in addition we offer installation and maintenance services to our esteem clients.

MFI offer aluminum melting furnace for making aluminum alloys. These aluminum melting furnaces are in high demand by our clients owing to its unique features such as Optimum productivity and Energy Efficient performance.

Aluminum/Lead Melting Rotary / Tilting Rotary Furnaces

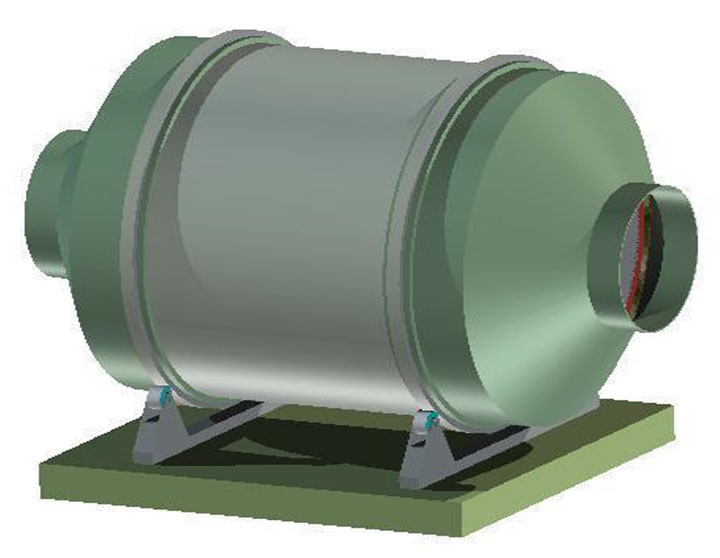

These types of Furnaces have a cylindrical shaped Melting chamber. The Burner is atone end and exhaust at the other end. Entire shell is placed on a steel structure havingfour rollers and is able to rotate on the rollers.

The Rotary Melting Furnace is very flexible and universal equipment used for recycling many non-ferrous metals. It is the major Aluminum production technology used in India and many other countries for Secondary Lead Production. A lead production system based on this technology has certain distinct characteristics such as:

Aluminum Melting Oil/Gas/Electric Crucible Furnaces

These types of Furnaces have a Melting Pot inside a round shell and a Burner/Electricalheating elements on one side. There may be either refractory or ceramic fiber lining inside the shell. A tilting mechanism can also be provided in this type of Furnaces.

Our furnace is made through heating element & design technology assuring the uniformresults of heating. Further on, our furnaces are fully auto controlled by means of PID.

Aluminum Ingot Casting Machine

Our Aluminum ingot casting machines have been designed and built to ensure long life. Having developed them, we know that they are amongst the most rugged and reliable on the market. Our aim is to give you maximum productivity and minimum downtime.

Aluminum Cold Dross Processing Machine

Ball Mill

Magnetic Separator

Aluminum Cold Dross Pulverizer

There are several techniques for recycling aluminium dross, however aluminium dross in the Aluminium Dross Pulverizers is the best way to save the aluminium loss. At the same time, it may store energy for future dross recycling hence, it is the most direct way of energy conservation. The process of pulverising a solid substance of a given size involves applying an external force to it in order to destroy it and reduce it to bits that are smaller than the original size.

Aluminum Hot Dross Processing Machine

Hot aluminium dross separator, it is one kind of machine for dross recycling and recovery. It can make full use of dross, increase the benefit, save the labour, minimize the dust and smoke problem, and make the waste into useful thing.

Hot aluminium dross separator is also known as dross machine. It is applied for all aluminum processing factories such as electrolytic aluminum plant, aluminum plant, and alloy aluminum plant where metal aluminium is the raw material and the production process is to melt aluminium. It can be used to automatically separate the aluminium dross whose temperature is above 700 ° C Besides; the equipment can also make use of high-temperature aluminium ash to melt thin aluminium, such as cans, aluminium scraps and so on. Compared with the cold treatment of aluminium ash, the use of this equipment features in characteristics of a small metal burning rate, energy saving, environmentally friendly, short production process and small investment.